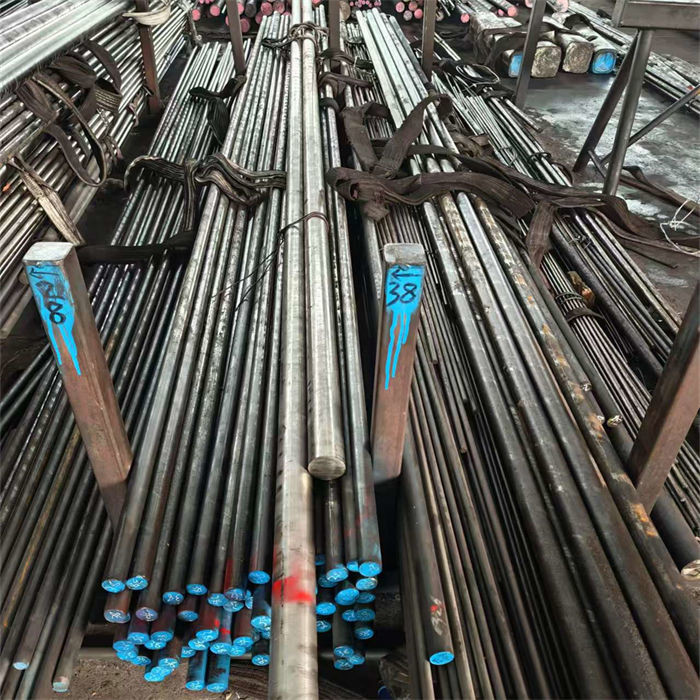

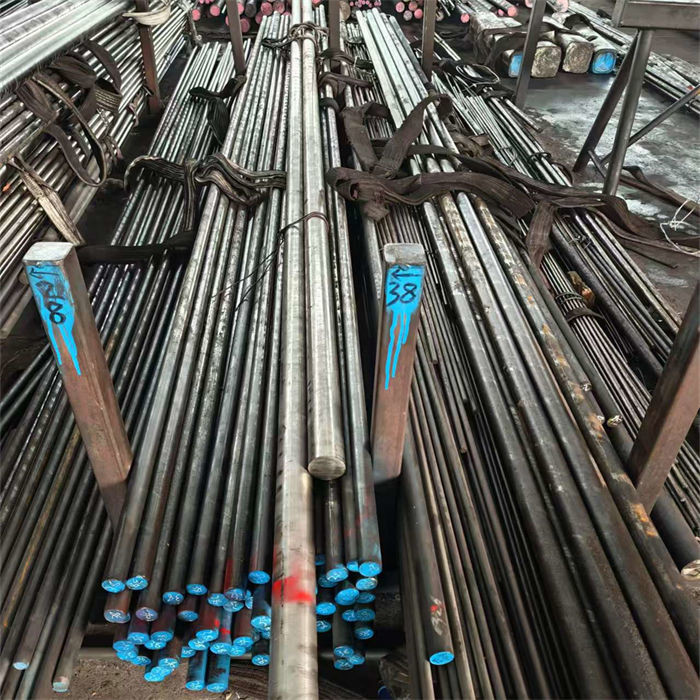

High Strength CD4MCu Round Steel 0Cr26Ni5Mo2Cu3 Forged Rod Duplex

Stainless Steel Rod.

Material introduction: Full name of brand: 0Cr26Ni5Mo2Cu3

Alloy CD-4MCu is nominally 26Cr-6Ni alloy (C≤0.04) with molybdenum

and copper added. There is no corresponding deformed steel for this

alloy. Alloy CD-4MCu is a two-phase structure in the cast state,

consisting of austenite distributed in a ferrite matrix. Although

carbide precipitation is limited by the minimum carbon content of

the alloy, if it is not eliminated by solution treatment, it will

also be dispersed in the ferrite matrix, thereby reducing corrosion

resistance. The solution treatment temperature of CD-4MCu is 1120℃,

and it is kept warm for at least two hours to ensure uniform

temperature, and then slowly cooled to 1010~1065℃, kept warm for

half an hour, and then quenched. Keeping warm at a lower

temperature is to avoid cracking of castings (especially castings

with thicker sections) during quenching. The structure after heat

treatment is also two-phase, containing 35~40% austenite in the

ferrite matrix.

Alloy CD-4MCu is basically ferritic, with a yield strength of about

twice that of 19Cr-9Ni austenitic alloy, and has high hardness,

good tensile plasticity and satisfactory impact toughness. The high

strength and hardness of the alloy are combined with excellent

corrosion resistance, making it particularly suitable for use under

corrosive (including abrasion and erosion) working conditions.

Alloy CD-4MCu has better corrosion resistance than CF alloy in many

corrosive media, and is widely used in strong acid working

conditions of oxidation and reduction, and has special resistance

to stress corrosion cracking in chlorine environments.

After solution treatment, CD-4MCu alloy can be further strengthened

by precipitation hardening caused by aging at 480-510℃. The degree

of aging reaction, as well as all the properties of the alloy in

the aged state, including corrosion resistance, strength, impact

toughness and quenching cracking tendency are related to the

complex phase treatment method, that is, the high or low solution

treatment temperature, aging temperature and aging time. Because

the alloy has sufficient strength and excellent corrosion

resistance in many applications after solution treatment, it is not

often used in the aged state.

The chemical composition of CD4MCu mainly includes the following

elements and their contents:

Carbon (C): ≤0.04%

Manganese (Mn): ≤1.0%

Silicon (Si): ≤1.0%

Phosphorus (P): ≤0.04%

Sulfur (S): ≤0.04%

Chromium (Cr): 24.5% - 26.5%

Nickel (Ni): 4.75% - 6.00%

Molybdenum (Mo): 1.75% - 2.25%

Copper (Cu): 2.75% - 3.25%

| C | Mn | Si | P | S | Cr | Ni | Mo | Cu |

| ≤0.04% | ≤1.0% | ≤1.0% | ≤0.04% | ≤0.04% | 24.5% - 26.5% | 4.75% - 6.00% | 1.75% - 2.25% | 2.75% - 3.25% |

These chemical compositions are the basis of CD4MCu's performance,

giving it excellent corrosion resistance and mechanical properties.

CD4MCu is a high-performance cast duplex stainless steel, widely

used in chemical, papermaking, food processing, marine engineering

and other fields, especially in the manufacture of pumps, valves

and other components.

The hardness of CD4MCu stainless steel is usually between HB200-320

and the density is about 7.8g/cm³.

| hardness | HB200-320 |

| density | 7.8g/cm³ |

Advantages and Disadvantages of Corrosion Resistant Alloy CD4MCu.

Corrosion Resistant Alloy CD4MCu is an alloy material with

excellent performance in high temperature and corrosive

environments. It is composed of a variety of elements, including

chromium, nickel, cobalt, tungsten, etc., which give CD4MCu

excellent corrosion resistance and high temperature strength

properties. However, like any material, CD4MCu also has its own

advantages and disadvantages.

Advantages:

1. High temperature strength: CD4MCu can still maintain high

strength at high temperatures, making it an ideal choice for

equipment that needs to withstand high temperatures and heavy

loads.

2. Corrosion resistance: The alloy has excellent corrosion

resistance and can resist erosion by various acids, alkalis, salts

and other chemicals. This makes CD4MCu widely used in chemical,

petroleum, pharmaceutical and other fields.

3. Good welding performance: CD4MCu is easy to weld, and the

material properties remain good after welding. This reduces the

difficulty of maintenance and repair and improves the reliability

of equipment.

4. Long life: Due to its excellent corrosion resistance and high

temperature strength properties, CD4MCu has a long service life,

reducing the frequency and cost of equipment replacement.

5. Good processing performance: CD4MCu is easy to process and

manufacture, and can adapt to various complex shapes and

structures. This reduces the difficulty and cost of manufacturing.

Disadvantages:

1. High cost: Since CD4MCu is a high-performance alloy material,

its manufacturing cost is high. For some projects that require a

large amount of this material, the budget may be limited.

2. Brittleness: CD4MCu may exhibit brittleness under certain

conditions, which may cause sudden cracks or breaks in the

equipment during operation. Therefore, special attention should be

paid to its operating environment and conditions when using CD4MCu.

3. Sensitivity and environmental factors: CD4MCu is sensitive to

certain chemicals and environmental factors, such as chloride ions,

hydrogen sulfide, etc. Special attention should be paid to these

factors when using CD4MCu to avoid adverse effects on its

performance.

In short, the corrosion-resistant alloy CD4MCu has many advantages,

making it an ideal choice in many fields. However, it is also

necessary to pay attention to its disadvantages and take

corresponding measures to ensure its safe and reliable use. When

selecting and using CD4MCu, it is necessary to evaluate and make

decisions based on actual needs and conditions.