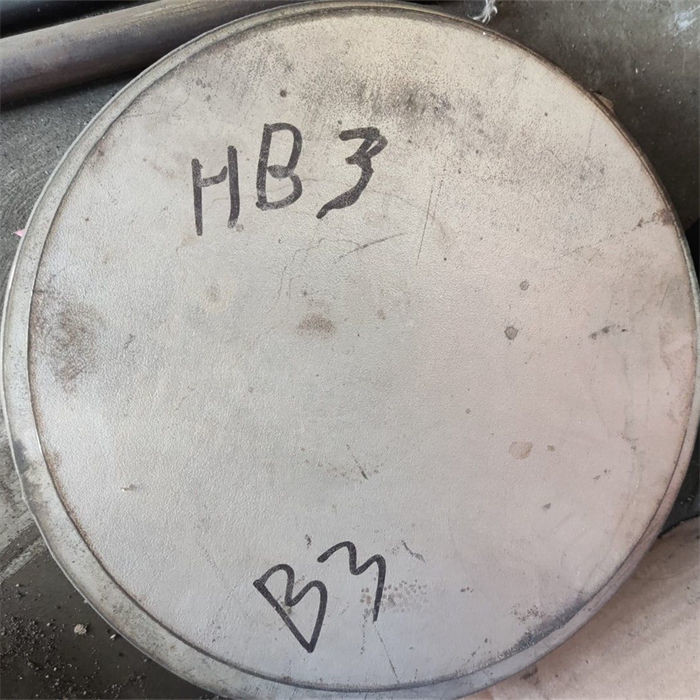

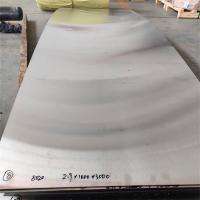

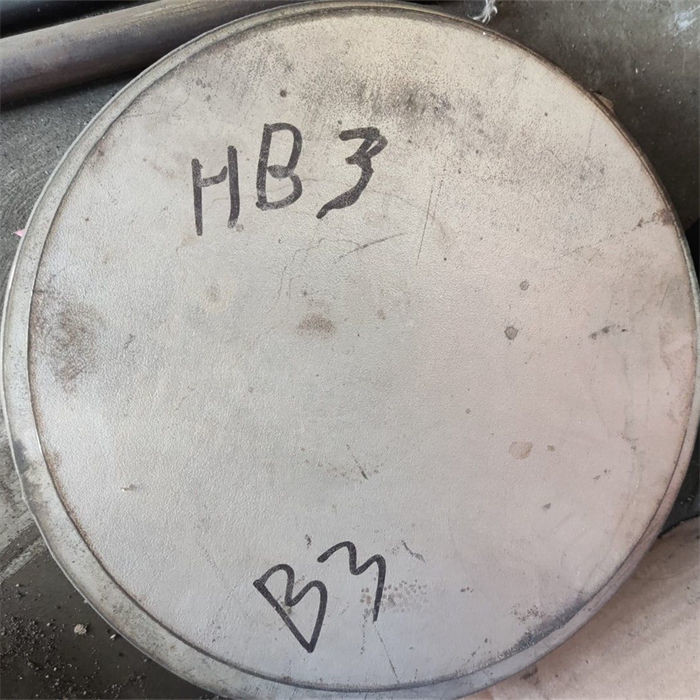

High performance corrosion-resistant Hastelloy B-3 sheet with

complete size and thickness, cut into circles

Introduction to Hastelloy B-3:

Hastelloy B3 is a nickel molybdenum alloy mainly added with

elements such as chromium and iron.

Hastelloy B3, also known as Alloy B3 or UNS N10675, is a nickel

based corrosion-resistant alloy with excellent corrosion

resistance, especially in strong acid environments such as

hydrochloric acid. Its chemical composition includes about 65%

nickel, 28% molybdenum, 2% iron, and an appropriate amount of

chromium.

Hastelloy B-3 chemical composition

| Ni | Mo | Fe | Cr | C(maximum) | Co(maximum) | Mn(maximum) | Si(maximum) | Ti(maximum) | W(maximum) | Al(maximum) | Cu(maximum) |

| ≥ 65.0 | 27.0-32.0 | 1.0-3.0 | 1.0-3.0 | 0.01% | 3.0% | 3.0% | 0.10% | 0.2% | 3.0% | 0.50% | 0.20% |

Nickel (Ni): ≥ 65.0

Molybdenum (Mo): 27.0-32.0

Iron (Fe): 1.0-3.0

Chromium (Cr): 1.0-3.0

Carbon (C): 0.01% (maximum)

Cobalt (Co): 3.0% (maximum)

Manganese (Mn): 3.0% (maximum)

Silicon (Si): 0.10% (maximum)

Titanium (Ti): 0.2% (maximum)

Tungsten (W): 3.0% (maximum)

Aluminum (Al): 0.50% (maximum)

Copper (Cu): 0.20% (maximum)

physical property

Density: 9.24g/cm ³

Melting point; 1370-1418℃

application area

Aerospace: Due to its excellent high-temperature performance,

Hastelloy B-3 can be used to manufacture aerospace engine parts and

rocket engine nozzles.

Oil and gas industry: Hastelloy B-3 can be used to manufacture

downhole tools and production equipment in the process of oil and

gas exploration and development.

Chemical industry: In the chemical production process, Hastelloy

B-3 can be used to manufacture equipment such as reactors and heat

exchangers to resist corrosion from corrosive media such as acids

and alkalis.

Pharmaceutical industry: Hastelloy B-3 can be used to manufacture

pharmaceutical equipment and pipelines in the pharmaceutical

production process. Ensure the quality of drugs and the reliability

of production.

The advantages of Hastelloy B-3 mainly include excellent corrosion

resistance, good mechanical properties, high temperature stability,

and processability.

Excellent corrosion resistance: Hastelloy B-3 exhibits excellent

performance in various acidic media, such as hydrochloric acid,

sulfuric acid, formic acid, etc., with extremely high corrosion

resistance. This alloy has excellent resistance to hydrochloric

acid corrosion at various concentrations and temperatures, as well

as good resistance to corrosion in non oxidizing environments such

as sulfuric acid, acetic acid, formic acid, and phosphoric acid.

These characteristics enable Hastelloy B-3 to be used for a long

time under extreme conditions, maintaining stable operation of the

equipment.

Good mechanical properties: The tensile strength of Hastelloy B-3

is usually above 480 MPa, the yield strength is usually above 205

MPa, and the elongation is usually above 40%, demonstrating good

ductility. These mechanical properties ensure the reliability and

durability of the alloy in various application environments.

High temperature stability: Hastelloy B-3 has good thermal

stability, with a melting point of about 1330-1380 ° C, and

excellent high-temperature oxidation resistance and heat corrosion

resistance. This enables it to maintain stable performance under

high temperature and pressure conditions, making it suitable for

fields such as chemical, petrochemical, and marine engineering.

Good processing performance: Hastelloy B-3 can be processed through

various processing methods such as forging, hot rolling, cold

drawing, welding, etc., and can be made into parts of various

shapes and sizes. This excellent processing performance enables

Hastelloy B-3 to adapt to the manufacturing needs of various

complex parts.

In summary, Hastelloy B-3 has been widely used in various fields,

including chemical industry, petrochemicals, marine engineering,

aerospace, etc., due to its excellent corrosion resistance, good

mechanical properties, high temperature stability, and

processability