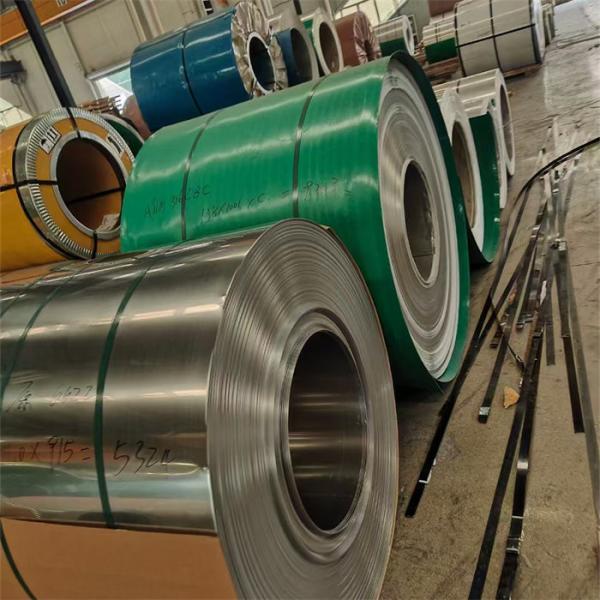

310S industrial mirror steel coil 316L stainless steel coil

processing cold rolled coil laminating slitting

ISO certified metal coil 0.01-20mm thickness uncoiling service

310S stainless steel strip is a high alloy stainless steel strip

belonging to the 25Cr-20Ni series, with excellent high temperature

oxidation resistance and good corrosion resistance.

310S heat-resistant steel is an important material in the aerospace

and chemical industries and is widely used in high-temperature

environments. High-temperature oxidation is the most common and

important form of corrosion damage at high temperatures. Therefore,

research and development of new materials with high-temperature

oxidation resistance has far-reaching significance for my country's

aviation industry, chemical industry and national defense [1].

Austenitic heat-resistant stainless steel 310S (0Cr25Ni20) is a

high-chromium-nickel austenitic stainless steel.

The role of nickel in stainless steel is only played after it is

combined with chromium.

Nickel is an excellent corrosion-resistant material and an

important alloying element for alloy steel. Nickel is an element

that forms austenite in steel, but in order to obtain a pure

austenite structure for low-carbon nickel steel, the nickel content

must reach 24%; and only when the nickel content is 27% can the

corrosion resistance of steel in certain media be significantly

changed. Therefore, nickel cannot constitute stainless steel alone.

However, when nickel and chromium exist in stainless steel at the

same time, nickel-containing stainless steel has many valuable

properties.

Based on the above situation, it can be seen that the role of

nickel as an alloying element in stainless steel is that it changes

the structure of high-chromium steel, thereby improving the

corrosion resistance and process performance of stainless steel.

Material types

304 stainless steel strip, 304L stainless steel strip, 303

stainless steel strip, 302 stainless steel strip, 301 stainless

steel strip, 430 stainless steel strip, 201 stainless steel strip,

202 stainless steel strip, 316 stainless steel strip, 316L

stainless steel strip, 304 stainless steel coil, 304L stainless

steel coil, 316 stainless steel coil, 316L stainless steel coil,

etc.

Surface

BA surface, 2B surface, NO.1 (white leather), 2D surface, NO.4

(matte), HL (brushed), 8K surface, etc. The surface quality is

excellent and the brightness is good

Stainless steel strip is also called coil, coil, plate, plate roll,

and the hardness of the strip is also very different.

Characteristics of stainless steel: 1. Complete product

specifications and various materials; 2. High dimensional accuracy,

up to ±0.1mm; 3. Excellent surface quality and good brightness; 4.

Strong corrosion resistance, high tensile strength and fatigue

resistance; 5. Stable chemical composition, pure steel, low

inclusion content; 6. Intact packaging and favorable price; 7.

Non-standard customization is available.

| Parameter | Value |

|---|

| Product | Steel Slit Coil, Stainless Tape Coil, Stainless Steel Coil |

| Thickness | 0.01-20mm |

| Material | Stainless Steel |

| Surface Treatment | Bright |

| Payment Term | Mainly T/T.. L/C, D/A, D/P, |

| Standard | ASTM,AISI,JIS,EN,DIN,GB |

| Width | 1000-2000mm |

| Length | 1000-6000mm |

310S stainless steel coil has the following main features:

High temperature resistance: 310S stainless steel coil has good

high temperature resistance, the working temperature can reach

1200℃, and the continuous use temperature can reach 1150℃.

Oxidation resistance and corrosion resistance: Due to its high

content of chromium (24.00%~26.00%) and nickel (19.00%~22.00%),

310S stainless steel coil exhibits excellent oxidation resistance

and corrosion resistance at high temperatures, and can operate

continuously in high temperature environments.

Mechanical properties: 310S stainless steel coil has excellent

mechanical properties, with a tensile strength of not less than 520

MPa, a yield strength of not less than 205 MPa, and an elongation

of not less than 35%.

Processing and welding properties: 310S stainless steel coil has

good processing and welding properties, and is suitable for various

processing techniques.

Application areas: It is widely used in petroleum, chemical,

electric power, boiler and other industries, and is often used in

high temperature environments such as furnace components and

automobile purification devices.

Differences between 310S stainless steel coil and 310SI2 stainless

steel coil:

Composition difference: 310SI2 stainless steel coil contains

silicon (1.50%~2.50%), while 310S stainless steel coil does not

contain silicon. This composition difference affects their physical

and chemical properties.

High temperature resistance: 310SI2 stainless steel coil has a

higher temperature tolerance range, up to 1300℃ or more, and

exhibits stronger creep resistance and oxidation resistance at high

temperatures.

Application scenarios: 310SI2 stainless steel coil has a wider

range of applications in aerospace, automobile, machinery and other

fields, especially in situations where long-term corrosion

resistance and high temperature resistance are required.

FAQ:

Q: What is the model number of this stainless steel coil?

A: The model numbers of this stainless steel coil are 304, 316,

304L and 316L.

Q: Where is this stainless steel coil made?

A: This stainless steel coil is made in China.

Q: What sizes are available for this stainless steel coil?

A: This stainless steel coil is available in multiple sizes.

Q: Is this stainless steel coil corrosion resistant?

A: Yes, this stainless steel coil is corrosion resistant.